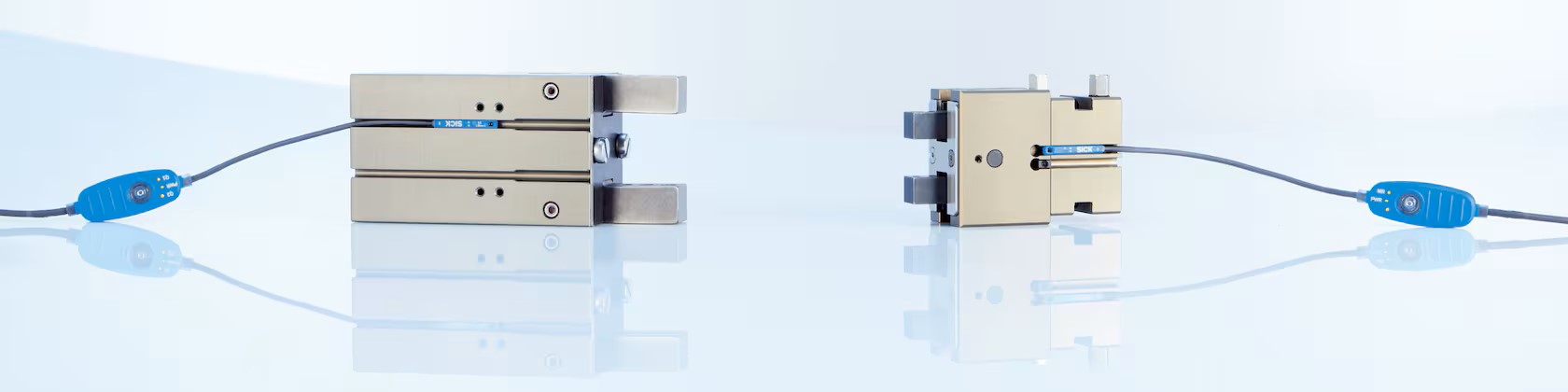

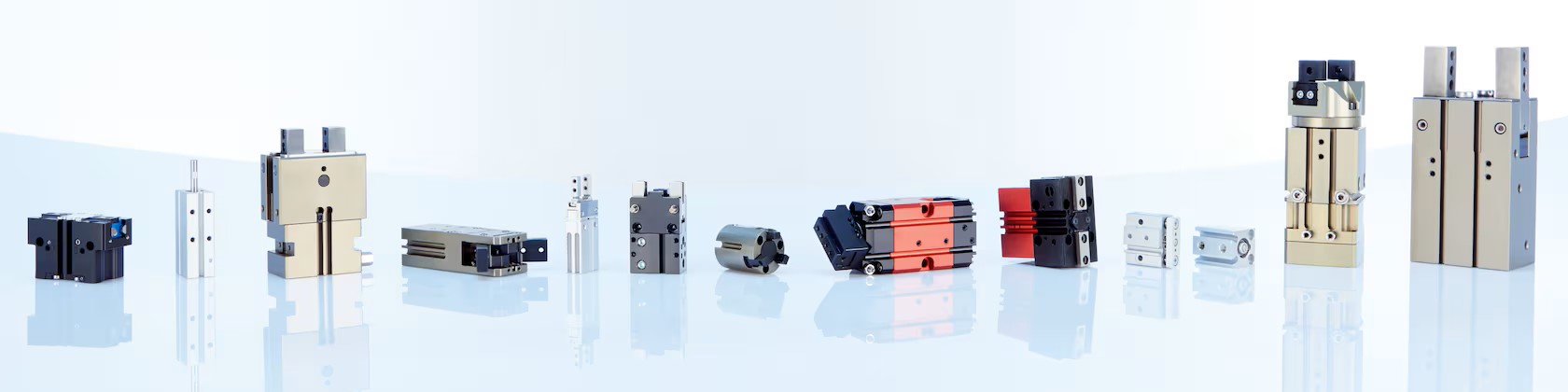

Very short position sensors for grippers and miniature cylinders

MPS-G position sensors continuously detect the position of the fingers of a pneumatic gripper and the piston position in miniature cylinders using a non-contact method. The compactly built magnetic distance measuring system determines these positions with micrometer precision. The sensor can be easily inserted into C-slots or, with the help of an adapter, into T-slots and is simple to fasten to a drive. The MPS-G is available in two product variants: as a sensor with an analog voltage output and as an IO-Link sensor with a Smart Sensor profile and three configurable digital outputs. SICK is thereby able to offer suitable solutions for numerous application requirements. The MPS-G also delivers comprehensive diagnostic data via IO-Link, including performance data for pneumatic drives or data for condition monitoring of systems.

MPS-G AT A GLANCE

Benefits

-Definition of two, three or more switching points to differentiate between gripper positions and several objects

-Simple measurement of components with absolute position value

-Micrometer-accurate detection of very small object tolerances

-Fits in all standard C-slots used around the world or in T-slots in conjunction with an adapter, regardless of the gripper and cylinder profile

-Saves time on initial installation and when replacing devices as the sensor can be inserted into the slot from above. The end caps of the drive do not have to be removed.

-Predictive condition monitoring of pneumatic drives and machine processes via an actuator and process diagnosis function

Features

-Position feedback with a measuring range of up to 50 mm

-Up to 3 digital switching signals

-8 switching points via IO-Link

-Dynamic teach-in for up to 3 switching signals

-Actuator diagnosis data: piston velocity, cylinder stroke, magnetic field strengths, etc.

-Process diagnosis data: temperature, vibration, position, max. acceleration

ADVANTAGES

Perfectly integrated

Perfectly integrated

The MPS-G position sensor was developed in accordance with the requirements of handling and assembly and robotics. This means not only an extremely compact sensor design for the C-slot, but also high resistance of the components used and durability of materials.

The MPS-G covers a detection range of 50 mm – and at a sensor head length of only 25 mm

Installation of the MPS-G in the sensor slot without any interfering contours is excellent protection against mechanical damage for moving applications

The right connection cable between the sensor head and the operating element for any mounting situation

Continuous position query - perfectly adjusted to grippers and small pneumatic cylinders.

Can be flexibly adapted to any requirement - with innovative operating concepts

Can be flexibly adapted to any requirement - with innovative operating concepts

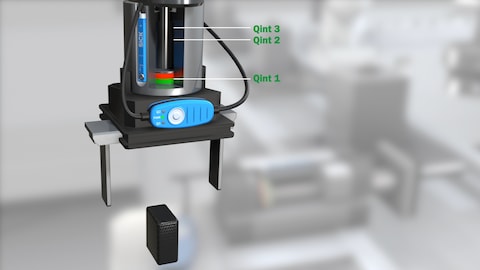

Every application is different. And with the MPS-G, there is always a solution for nearly any detection task: Querying gripper finger positions, measuring workpieces, monitoring press-fit processes or simply precisely detecting end positions. The highly accurate position values can be used either as analog signals and as process data via IO-Link or translated into digital switching information and used as such.

Ideal for varying workpiece sizes and component tolerances

Switching signals can be generated flexibly and individually from the absolute position values

With the innovative dynamic teach-in, the sensor adjusts the switching points on its own

As a high-precision magnetic distance measuring system, the MPS-G delivers a position value and two, three or more switching points to differentiate between gripper and cylinder positions. The functional scope and the configuration options of the sensor depend on the communication interface and the selected teach-in option.

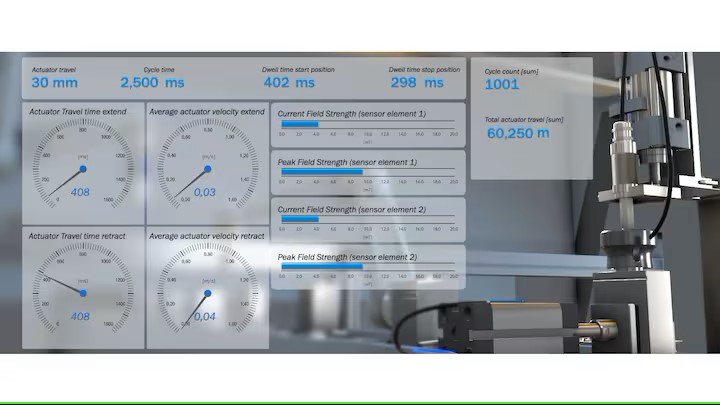

Condition monitoring of pneumatic drives

Condition monitoring of pneumatic drives

Pneumatic drives wear like any other mechanical component. With the MPS-G, however, critical components can be identified, readjusted or exchanged in a timely manner, thereby preventing unplanned machine downtime. The MPS-G ensures more process transparency for actuators and machines. Unauthorized intervention by operating staff can also be tracked using the position sensor. The MPS-G delivers basic data for optimal adjustment and condition monitoring of pneumatic drives – and without installing any other components.

The MPS-G delivers data on possible wear or if the cylinders are not optimally adjusted

Traversing speed, cylinder travel, dwell time in the end positions and magnetic field strength are only some examples of diagnostic data the MPS-G generates

The MPS-G delivers basic data for optimal adjustment and condition monitoring of pneumatic drives – and without installing any other components.

Diagnosis

Diagnosis

Equipped with a wide range of diagnostic functions, Smart Sensors make it possible to look into the future in order to detect process deviations in advance and prevent unplanned machine or system downtime. In addition to the actual sensor data, Smart Sensors can deliver other valuable in on the status of the machine, plant or process.

Smart Sensors will send a notification independently if safe operation is at risk. Thanks to predictive maintenance, flexible, needs-based maintenance schedules can be created, helping reduce service costs. If problems should arise, however, the cause can be easily determined thanks to comprehensive visualization options, avoiding unplanned system downtime.

Vibration analysis

Defective, worn or loose components change the characteristic vibration pattern of machines. The MPS-G Smart Sensor with diagnostic functions analyzes and monitors the vibration of critical components in the machine in the time and frequency range.

Temperature measurement

Temperature monitoring helps ensure process and product quality. The MPS-G Smart Sensor with diagnostic function records changes in the application temperature.

Orientation monitoring

The Smart Sensor with diagnostic functions makes it possible to monitor its own orientation or the orientation of the machine part on which it is mounted.

Highest availability levels thanks to predictive maintenance

Untitled

Inquiry - MPS-G