Way above the standard – the economic way to business class

The photoelectric sensors in the G6 product family with their miniature housings will impress you across the board with both their standard mounting configuration of 1-inch spaced holes and also their functional characteristics. The variants with a stainless steel 1.4404 (316L) housing are especially resistant to chemicals and cleaning agents in washdown applications. With PinPoint LED and laser technology, metal inserts for mounting, large and bright indicator LEDs, user-friendly adjustment screws, IP67 and IP69K enclosure ratings, as well as the very latest ASIC technology from SICK, the G6 series far exceeds the current standard.

G6 AT A GLANCE

Benefits

-PinPoint LEDs (with visible red light and infrared light) or variants with a laser light spot enable objects to be detected reliably and are therefore suitable for a broad range of applications

-Superior optical performance and robustness thanks to the ASIC from SICK

-Quick and easy mounting and high durability thanks to the metal inserts with M3 thread

-Easy installation and adjustment with user friendly potentiometer and highly visible indicator LEDs

-Variants with a stainless steel housing and IP69K enclosure rating ensure a long sensor service life in demanding washdown applications

Features

-PinPoint LED and class 1 laser variants

-SICK ASIC, the result of decades of experience with photoelectric sensors

-Photoelectric proximity sensors with background suppression, energetic photoelectric proximity sensors, and through-beam photoelectric sensors

-ABS plastic housing and V4A stainless-steel 1.4404 (316L) housing

-Enclosure ratings IP67 and IP69K

ADVANTAGES

Way above the standard – the economic way to Business Class

Way above the standard – the economic way to Business Class

The photoelectric sensors of the G6 product family use both PinPoint LEDs and laser technology. They come in a 1-inch housing mounted using metal inserts with M3 threaded holes. The G6 product portfolio also offers maximum flexibility for solving your application requirements.

Simple alignment using the PinPoint LED Precise, highly visible light spot for easy sensor alignment, even under difficult application conditions

Easy mounting due to metal inserts with M3 thread For quick and easy mounting

Easy adjustment thanks to user-friendly potentiometer Quick installation and commissioning

The G6 product family offers an extensive portfolio of photoelectric sensors for object detection which are suited for a wide range of applications.

Quick to mount and ready to operate right away

Quick to mount and ready to operate right away

Thanks to the reinforced metal inserts with M3 threaded holes, the G6 photoelectric sensor located in the miniature housing can be mounted quickly and securely. This means the photoelectric sensor is ready for use right away to demonstrate its high performance in your manufacturing processes.

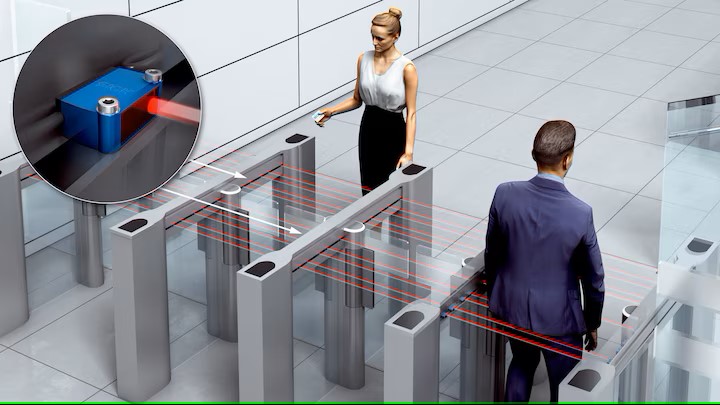

Thanks to the PinPoint LED, the singulation of persons at access points is child’s play for the G6 miniature photoelectric sensor. Due to its compact design, the G6 also does not need much space. This means several sensors can be used for this application if needed.

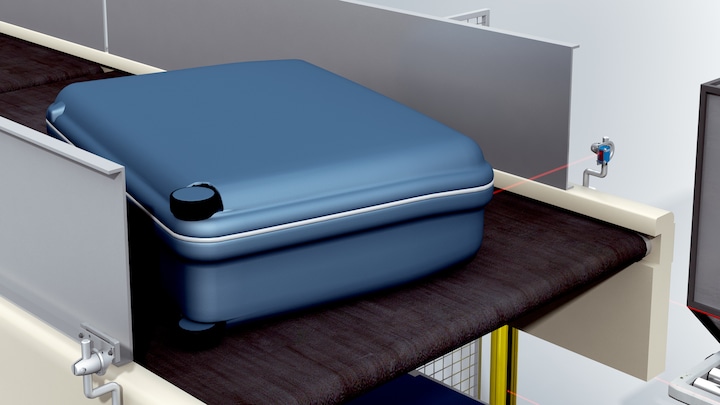

The G6 can be adjusted quickly, ensuring smooth processes at transfer points for baggage.

With PinPoint LED and secure mounting, the G6 product family is a low-price and user-friendly solution for countless applications

Reliable detection of delicate objects

Reliable detection of delicate objects

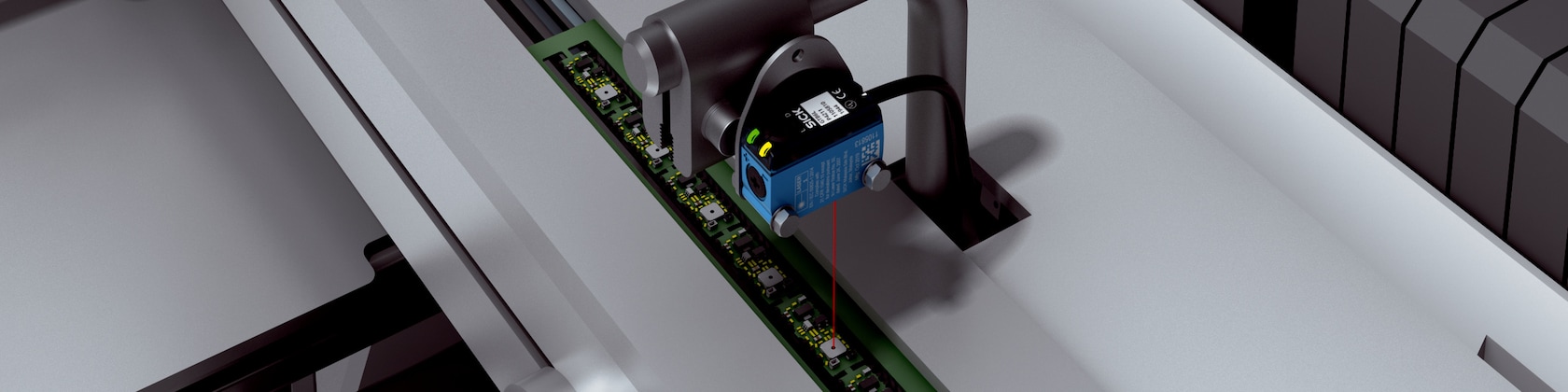

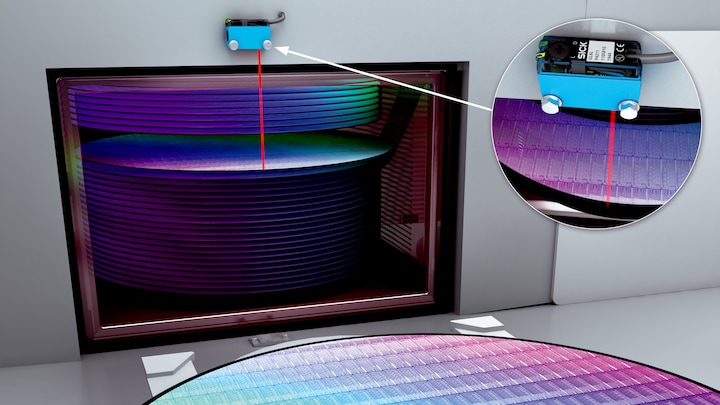

In addition to its optimal performance, the G6 photoelectric proximity sensor also features a space-saving 1-inch housing. This enables a high level of flexibility in the machine design. The precise laser detection also ensures excellent sensor performance, even under difficult conditions. The G6 laser is therefore perfectly suited for the detection of small parts in electronics production.

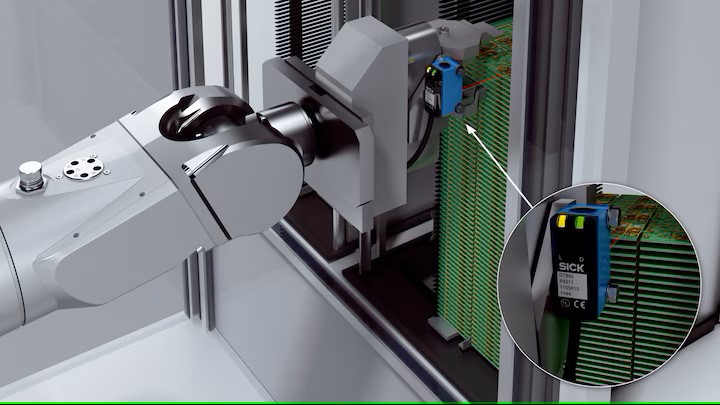

The G6 laser portfolio features photoelectric proximity sensors with background suppression and energetic photoelectric proximity sensors with a sensing range of 400 mm and a light beam diameter of 0.4 mm. That is why the G6 laser is perfect for integration into robot arms and use in automation engineering.

Thanks to its small light beam diameter, the G6 laser is perfect for the detection of wafer discs in handling processes in the semi-conductor industry.

With its laser light spot, the large sensing distance and precise detection, the G6 laser is the ideal solution for many industrial applications.

Rugged and reliable – stainless-steel sensors for washdown applications

Rugged and reliable – stainless-steel sensors for washdown applications

With G6 Inox sensors, it's all about using devices that offer maximum reliability under very harsh ambient conditions to optimize production processes. Due to their rust-free stainless-steel housing, the sensors are highly durable. And their high chemical material resistance means they are a reliable option when faced with cleaning agents containing alcohols and alkalis as well as standard oils and lubricants. Thanks to these significant advantages, the G6 Inox sensors are ideal for use in the food and beverage industry. In this sector, hygiene takes top priority and is ensured by means of intensive cleaning and disinfection processes.

Easy to identify even after long periods of use The indestructible laser inscription means that the sensors' type designation will still be easy to read even after long-term use in a harsh environment.

Special coating on the PMMA front screen for additional resistance

The right sensor for your application – the rectangular housings of the G6 Inox product family offer great flexibility when it comes to installation and adjustment since the sensors can be installed with mounting brackets.

Always the first choice – particularly in harsh environments Due to their exceptional properties, G6 Inox stainless-steel sensors are particularly well-suited for use in industries with strict hygiene requirements and where ambient conditions can be harsh.

Untitled

Untitled

Untitled

Inquiry - G6