The flexible and efficient detection system in one chain

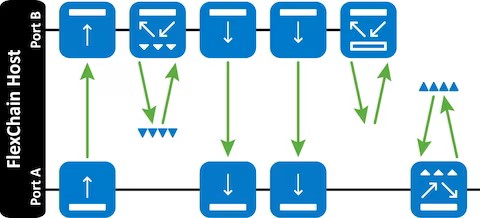

The FlexChain is a flexibly configurable light grid thanks to the sequential connection of several sensors. There is no need for long connection cables or complex wiring. By pressing a button on the FlexChain Host, the sensors can be addressed and taught-in automatically, meaning the system is immediately ready for use. Different sensor technologies can be combined and freely arranged: Through-beam photoelectric sensors, photoelectric sensors. The raw sensor data is evaluated via the FlexChain Host with integrated logic modules or forwarded directly via IO-Link, CANopen, RS-485 or I/O signals. Detailed diagnostic information ensures optimum process stability and measurement certainty during operation.

FlexChain AT A GLANCE

Benefits

-Flexibly expandable light grid system: Up to 60 sensors can be cascaded and controlled centrally via the FlexChain host

-Ready for operation immediately: The sensors are identified and taught in at the push of a button

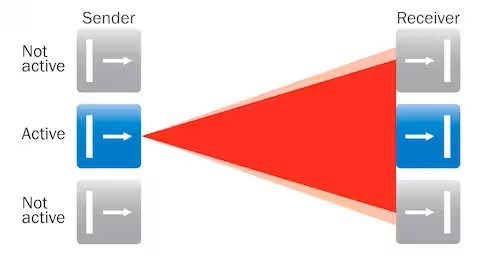

-Optimum measurement certainty thanks to sequential sensor cycling without mutual interference

-Highly flexible positioning of through-beam photoelectric sensors, photoelectric retro-reflective sensors, photoelectric proximity sensors and light grids at any distance or in any position

-High process stability thanks to extensive diagnostic function

-High flexibility due to logic configuration in the host and the IO-Link, CANopen and RS-485 interface variants

Features

-Ultra-simple wiring for up to 60 sensors

-Sequential cycling prevents mutual interference

-Free arrangement of various sensor technologies

-Sensors available in different lengths of cable

-Sensor data evaluation in the system or direct transmission of raw data

-Process stability thanks to diagnostic function

ADVANTAGES

.jpg)

Simple installation and implementation save time and money

Cascading the individual sensors saves on cabling and makes it easier to integrate them into the existing system. The sensor system is available with different pigtails. Even with complex arrangements, there is therefore no need to spend money on additional connections. FlexChain is remarkably quick to implement, as the entire system works as one unit without any complex wiring in the control unit.

More efficient integration

Cost-effective: The sensor comes with an integrated pigtail. There is no need for additional cables.

Minimal effort: Cascading makes cabling much easier compared against point-to-point connections.

Instant on: The FlexChain host detects all sensors automatically. Data transmission starts at the touch of a button.

The FlexChain adapter can be used to connect an arbitrary 24 V signal (e.g., proximity sensor, relay signal, or other standard sensor) to the system bus as an additional input.

Installation and implementation of FlexChain is remarkably simple. Automatic sensor detection and cascaded cabling also save time and money during system integration.

Greater flexibility with optimum measurement certainty

The light grid technology with sequential cycling prevents the signals of the individual sensors from overlapping. There is therefore no chance of obtaining incorrect measurement data. This means that narrow arrangements can be implemented without a rigid light grid, allowing them to be better adapted to the individual conditions of the system. In addition, the sensor technology can be freely selected based on requirements. As a result, FlexChain increases the ruggedness and flexibility of the application.

More flexible positioning

Optimum measurement certainty: Sequential cycling prevents the signals from overlapping

Freely positionable thanks to individual length of cables: Compared to conventional light grids, the beams can be positioned wherever they are needed.

FlexChain, the individual light grid: Whether through-beam photoelectric sensors, photoelectric retro-reflective sensors or photoelectric proximity sensors – the sensor technology can be freely selected and combined.

FlexChain can be flexibly adapted to the application on a case-by-case basis. The system delivers reliable results no matter which sensor arrangement or sensor technology is used.

Full transparency for system and sensor data

FlexChain also offers full flexibility for sensor data. These are either forwarded directly to the controller or evaluated with ease in the system itself. What’s more, FlexChain offers extensive diagnostic options: Parameters such as sensor information, contamination level, and communication status can be viewed at any time. This enables errors, failures and downtimes to be effectively prevented thanks to early recognition of problems.

Intelligent functionality

Intuitive operation: Define zones, configure logic, and monitor the sensors with ease using the SOPAS software tool – convenient connection of the FlexChain host via USB

Numerous interfaces: Whether IO-Link, CANopen, RS-485 or configurable switching outputs – integration into virtually any system is possible.

high process reliability: Diagnostic parameters from the sensors and system are available at any time to prevent downtimes or measurement errors

Whether it is flexible data transmission, the ability to work with various interfaces, or real-time diagnostics that you need – FlexChain can be conveniently and reliably integrated into virtually any environment

Inquiry - FlexChain